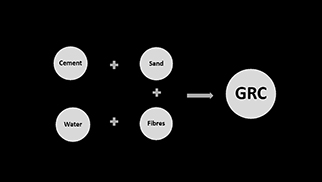

What is really in the Glassfibres Reinforced Concrete (GRC) planter?

January 1, 2020

Together! We learn things along the way

June 6, 2020Loading planters into container with Rosie Pottery

Let imagine that you open the container, then see so many planters broken and cracking? How do you feel at that time? TERRIBLE!!!

I. Why loading into container is so important, especially with planters?

- Container loading is a critical step in the shipment process of all products, specially of planters. Even if the planters are produced with good quality, damages to them (such as broken, crack, scratched surface) takes place if they are not loaded properly.

- Thus, the planter loading process should be in such a way that it should not affect the product at any stage of loading.

- To avoid the planter damage and to assure the quality, the “Container Loading Inspection” must be conducted at Rosie Pottery.

II. How Rosie Pottery put products in the container and control the process?

In our company, the loading process is separated into 3 stages: “before – during – after” loading

a. Before loading

For products, 1 – 2 days before the loading date, the quality staff shall check and confirm:

- The quantity and structure of pallet. That means “Is it correct with the Packaging Instruction or not?”

- The conformity of products. That means “Is it correct with the Order of customer or not?”

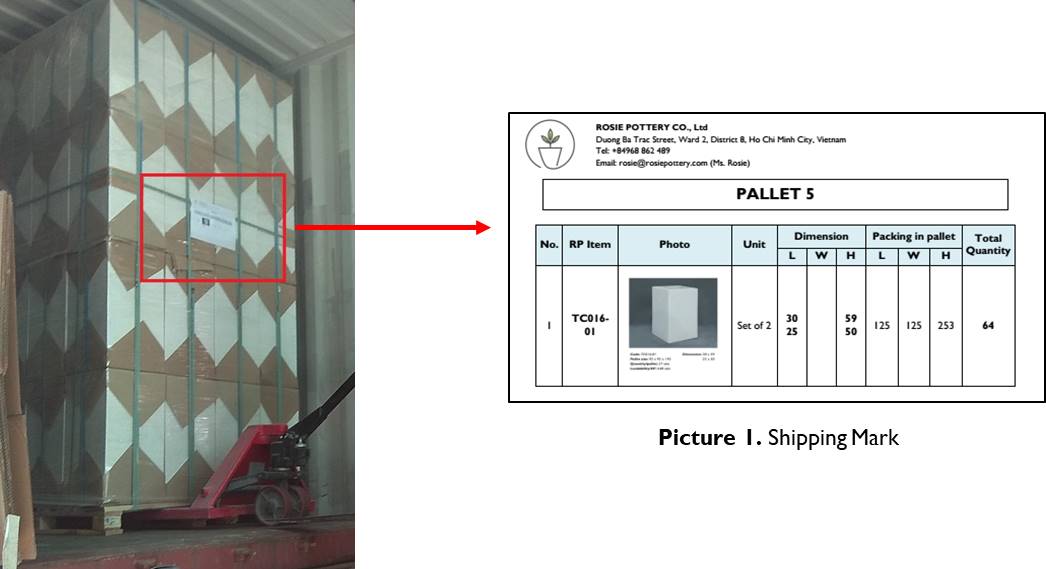

If all things are ok, then each pallet will be sticked the Shipping Mark. (see at Picture 1)

For container, we always discuss with the forwarder to have us the good container (no hole, broken, cracking), because our concern is that the hole make way for sea water get into the container. That will affect the planters.

| No. | Checking points | Why we set that point? |

| 1 | Pallet appearance (broken, cracking) | Cracking or broken pallets must affect the planters, because we don’t know how the container would be during international transportation. |

| 2 | Pallet fumigation | Being fined or may not import due to lacking pallet fumigation. |

| 3 | Pallet clearance | Some customers noticed us that may get fined if the pallet dirty. |

| 4 | Position of pallet in container | If loading step is not correctly handled, then the final pallet shall not fit, then we have to unload, adjust, load again. If this happen, there must be the possibility of planter damage. |

c. After loading

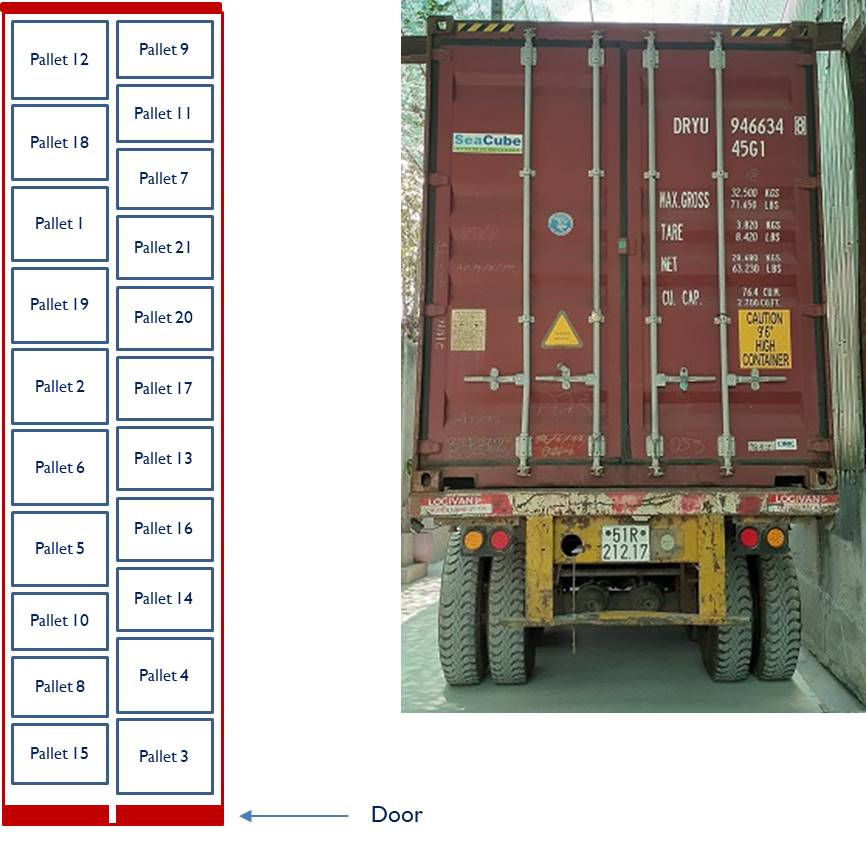

We will send to customer the layout of container. (See picture 2), so that our customers can know what exactly pallets they are unloading and easily to check the products.

III. What is the advantages for customers in our packaging?

You will get 3S from us

Rosie Nguyen - Vietnam, April 2020